Mikrotek manufactures polycrystalline diamond dies in the range of 0.025 – 30.000 mm

The dies are strictly manufactured as per customer-ordered specifications.

Our PCD dies are widely used to make most stainless steel, medical wires, low and high-carbon steel, welding wire, copper and aluminium conductors, magnets, EDM tungsten, molybdenum, coated and alloy wires, and more. We use customized profiles for both wet and dry drawing applications.

The PCD blanks are sourced from well-known manufacturers, mainly M/s Sandvik Hyperion (formerly Diamond Innovations/GE), M/s Sumitomo, and other reputed manufacturers. ‘Compax’ – the brand produced by Sandvik Hyperion – is very popular and widely used in the wire and cable industry.

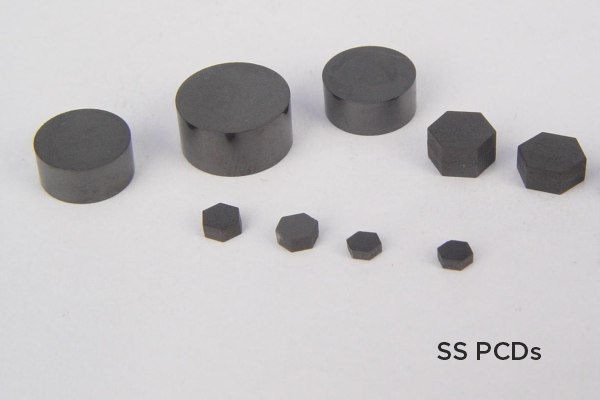

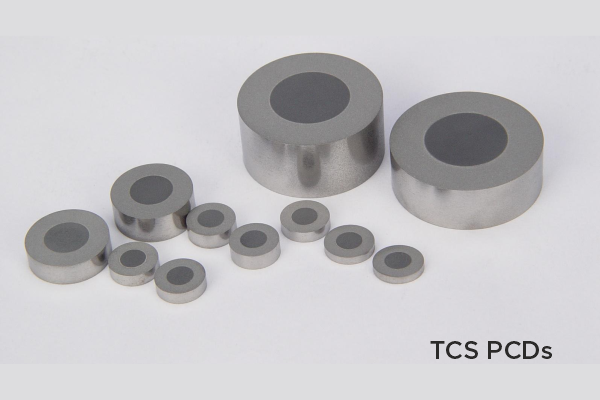

PCD blanks are available in two types – self-supported and tungsten ring-supported. They also come in different grain sizes of 1, 3, 5, 10, 25, and 50 microns.

The PCD blanks are manufactured in a high-temperature and pressure process. Cobalt is used as a binder between synthetic diamond particles. These are called metal-filled blanks and will withstand temperatures up to 650°C. The cobalt is leached out for high temperatures and special applications, and the blanks can withstand temperatures up to 1200°C. These are called thermally-stable blanks.

We always understand our customer’s needs and recommend the proper selection of PCD blanks depending on requirements such as wire surface, drawing speed, die life, and more.

Advantages:

Retention of roundness for a long time.

Less downtime of drawing machine.

Suitable for both wet and dry drawing.

Suitable for cold and hot drawing.